We’ve reached 156K followers! ✨🎉

Thanks to your amazing support and love, our page has grown to this milestone 🙌💙

To celebrate, we’re giving you $10 OFF 🎁💵

Coupon: 156kfollowers

Thanks to your amazing support and love, our page has grown to this milestone 🙌💙

To celebrate, we’re giving you $10 OFF 🎁💵

Coupon: 156kfollowers

In this tutorial, we will look into the specifications, features, wiring methods, software setup, programming, and debugging of the T-8000 LED controller.

The T-8000 is the boss of the T-Series offline Pixel LED Controllers. There are four main T-8000 series controllers, namely the T-8000, T-8000AC, T-8000C, and T-8000A-TTL. Keep in mind that the same model has different versions because every controller gets updated all the time. This controller is more expensive than the T-1000 series controllers, but it has some improved features.

T-8000 series Pixel LED controllers can drive up to 8192 Pixel LEDs or pixels. It has eight ports for LED strings or strips. Each port can drive up to 1024 Pixel LEDs. It has controller networking capability, as in the T-1000S LED controller. It supports 3 wire Pixel LED strings or strips (VC, Data, and GND) and 4 wire LED strings or strips (VC, Data, Clock, and GND). It also supports RS485-based Pixel LED strips or strings.

Frame rate is an important thing when it comes to Pixel LED programming. The higher the frame rate, the smoother the frame transition. A low frame rate means a rough transition, and you will start to see the frame-by-frame transition.

If you are using less than 512 LEDs or pixels per port, you can use 30 frames per second. If you are using more than 512 LEDs or pixels per port, the frame rate will automatically reduce.

Software plays the most important part when it comes to Pixel LED programming. LEDEdit is the most advanced and most developed Pixel LED programming software today. To program the T-8000 controller, you need LEDEdit 2014 or later software. Please download the latest LEDEdit software version from the below link.

When you are selecting the controller from the list, please follow this method.

Controller Name in the list = Controller Name + Drive Chip Name

If your controller name is T-8000 and your drive chip name is WS2811, you should select T-8000-WS2811 from the list.

If you are using T-8000S or T-8000A controllers, please select T-8000 as your controller. They are not listed because they are based on the T-8000 controller (different versions).

TM1803,TM1804,TM1809,TM1812,TM1829,TM1913,TM1914,UCS1903,UCS1903B,UCS1909B,UCS1912,UCS2903,UCS2909,UCS2912,UCS3903,UCS6909,UCS6912,UCS7009,UCS5903,UCS8903,UCS512,US2811,WS2821,P9813,P9823,LPD1886,GW6202,GW6201,GW6202B,GW6204,GW6203,GW623X,TA9909,MBI6021,INK1003,LX10003,LX2003,LX2006, TLS3100,DMX,SM16711,SM16726,SM16716,LPD6803,LPD8806,LPD1882,LPD6812,TM1903,TM1904,TM1909,TM1912,DMX Monochrome, WS2801,WS2803,D7710,QC1109,TLS3001,TLS3008,APA102,MY9221,BS0815,BS0825,BS0901,HL32,HL1809,HL2803,RGB Monochrome,XB001,XB002

Note: Not every T-8000 controller supports the above-listed drive chips. Please consider asking your seller about supported LED drive chip names.

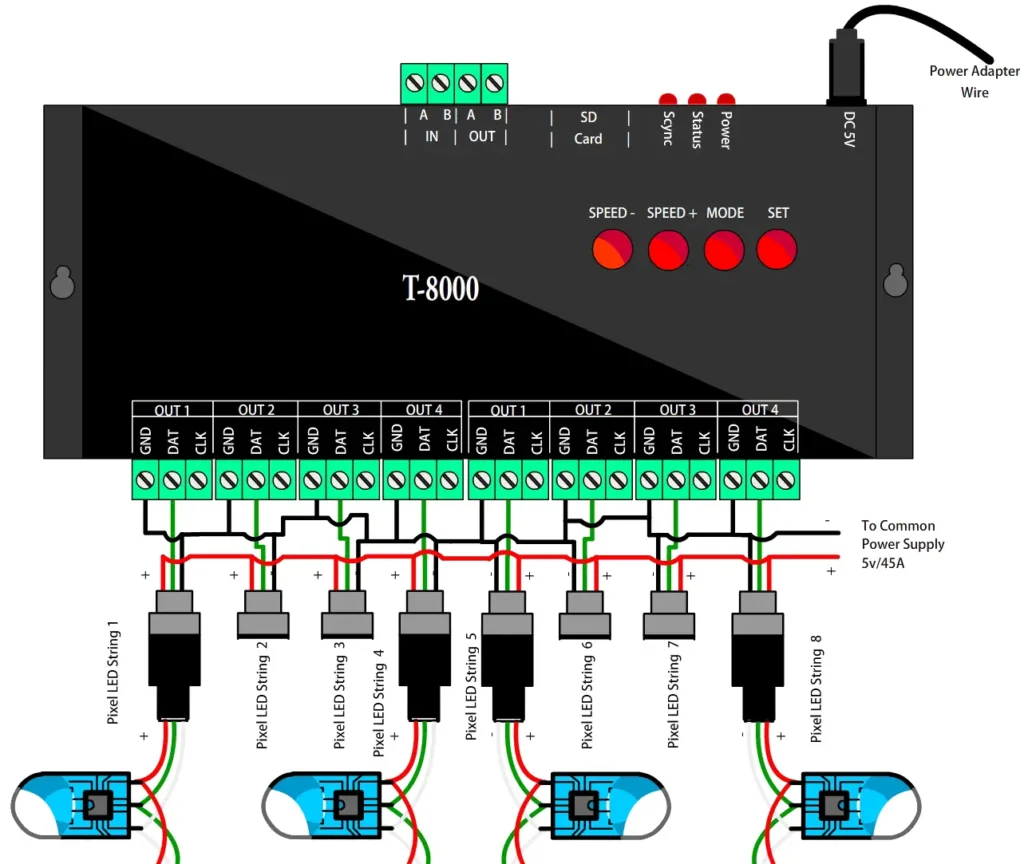

Please refer to the above picture for pin output definitions.

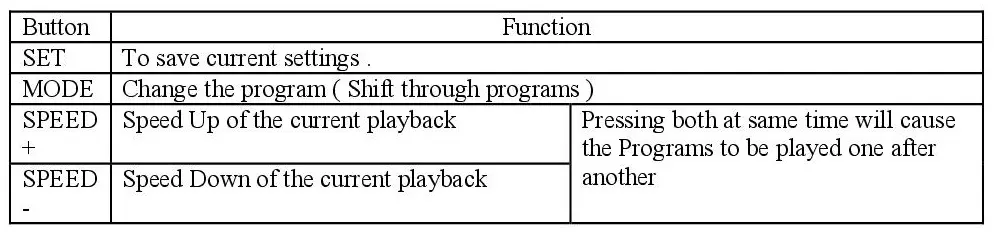

Button functions are the same as for the T-1000S LED controller. Here are the button functions.

If you want one program to be played, press and release the mode button quickly to skip to the next program. Keep tapping on the mode button until you get the program you want to play, and then press the “SET” button to save those settings.

If you need to change the speed of the playback, use the “SPEED+” button to increase the speed of the playback, and use “SPEED-” to reduce the speed of the playback. Once you reach the speed that you want, press the “SET” button to save the settings.

If you want the program to play one file after another, press both the “SPEED+” and “SPEED-” buttons together and release them. Then press the “SET” button to save the settings.

Make sure you press the “SET” button after every setting change. If not, upon the next powerup of the controller, you won't get the playback you wanted.

When it comes to T-8000 Series LED controllers, there are several different versions. Let's look at them.

The above picture shows one of the T-8000 controllers. This one has an AC input instead of a DC power input. Yes, there are many different versions of the same model number. There is a T-8000 controller with a DC 5V input, one with a 7–24V DC input, and one with an AC 110–230V input. This version doesn't have a display; it only has LED indicators. Other features remain the same.

This one is the same as the first (T-8000) controller; the only difference is that it has two RJ45 male ports instead of A and B input and output ports. These two ports can be used to network (synchronize) the controllers or to connect the T-8000C controller with the LED consoles.

This is the T-8000AC LED controller, which is designed to operate with an AC supply. It has a seven-segment display to show you details like current speed, mode, and status. This version has LED indicators as well. Supported voltage: 110–230 VAC.

This controller has an LCD display instead of a seven-segment display; other features remain the same.

To learn everything about the T-8000A TTL LED controller, click here or read the following guide.

Synchronization is very important when you have multiple controllers for your pixel LED pattern. If not, the pattern will be a mess. In the T-8000 Controller, the synchronization can be achieved by networking (cascading) the controllers together (please refer to the wiring examples below).

There are four wiring methods for this controller.

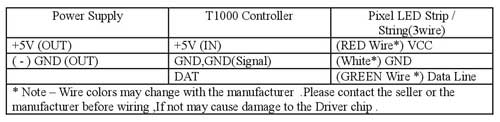

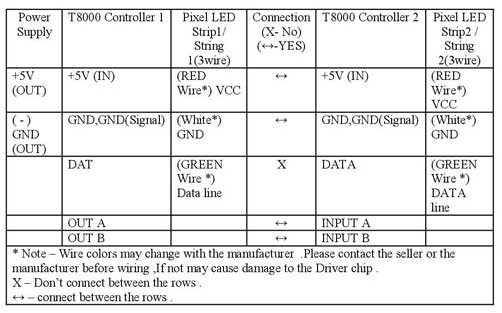

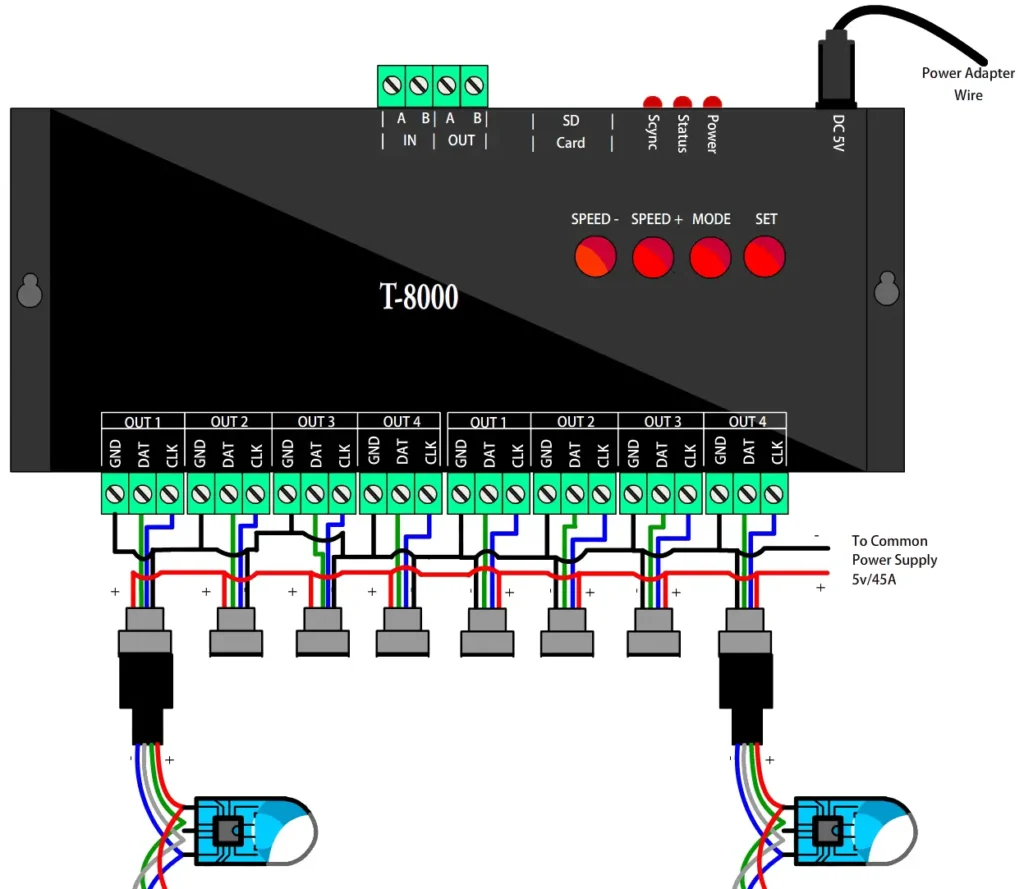

In this case, a single controller was used with eight sets of LED strings. The controller is connected to the 3-wire Pixel LED String or Strip, so only 2 wires of the controller are connected to the LED String (Data and GND). The controller is powered by an external 5V DC power adapter. A single power supply is used to power the LED strings. You can use two or more power supplies that can deliver the amount of amperage needed. (Click here to learn more about how to choose a power supply for a Pixel LED project). Here is the connection table.

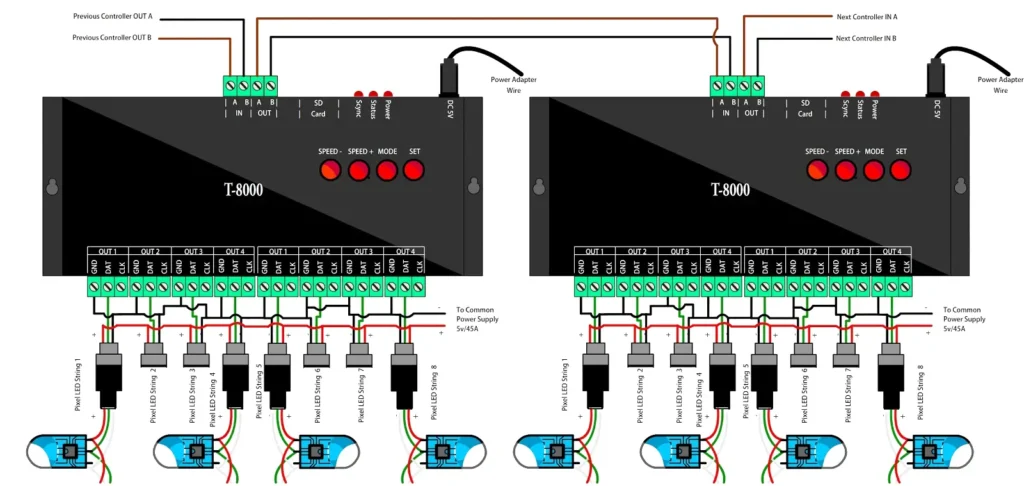

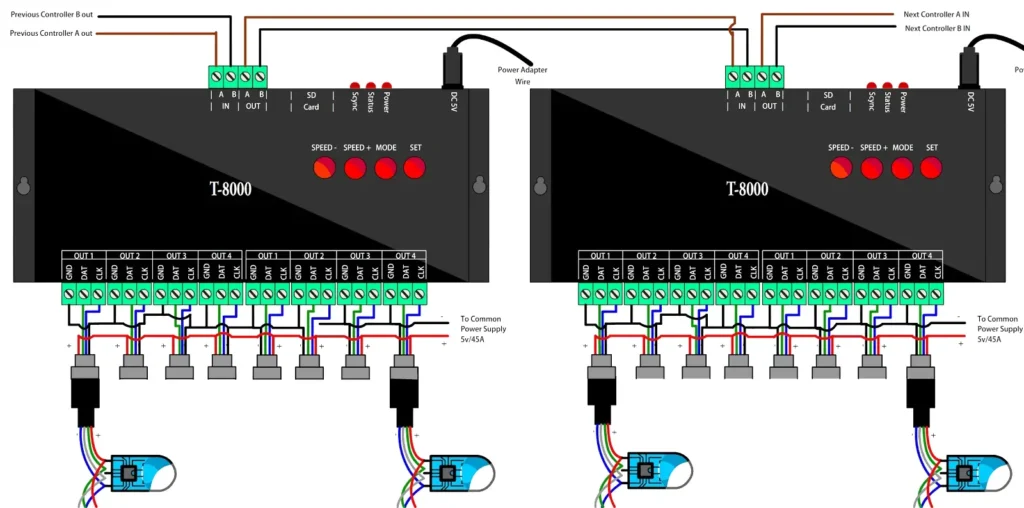

In this case, two T-8000 controllers are used with 16 sets of LED strings. The controller is connected to the 3 wire Pixel LED String or Strip, as in the previous example. The controllers are networked so that patterns can be synchronized. The controller is powered by external 5VDC power adapters. The benefit of this method is that you don't need separate SD cards for each controller. You can use a single SD card that contains all the pattern files for each controller. Here is the connection table.

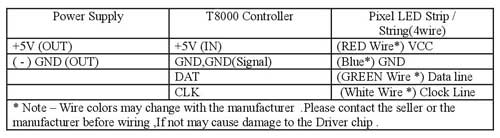

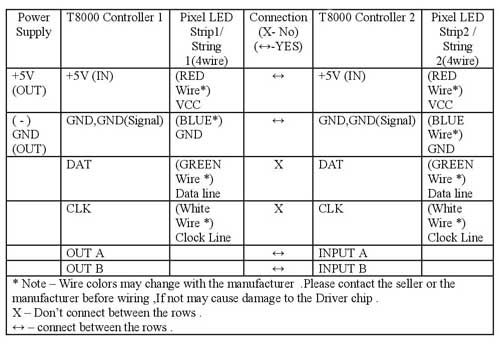

In this case, a single controller was used with eight sets of LED strings. The controller is connected to the 4 wire Pixel LED String or Strip, so 3 wires of the controller are connected to the LED String (Data Clock and GND). Here is the connection table.

In this case, two T-8000 controllers are used with 16 sets of LED strings. The controller is connected to the 4 wire Pixel LED String or Strip as in the previous example (Method 2). The controllers are networked so that patterns can be synchronized. Here is the connection table.

The program file placement inside the SD card depends on the controller's usage.

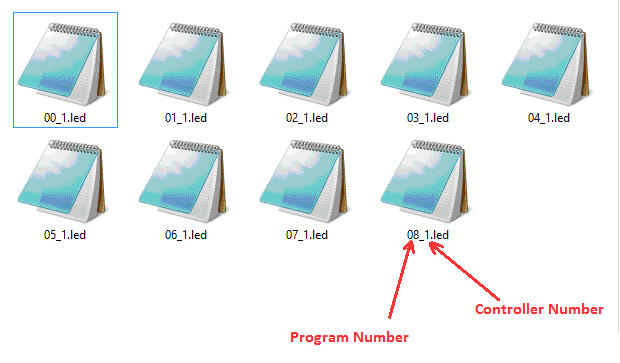

Single T-8000 controller file placement

If you are using a single controller or multiple controllers without networking them (in this case, every controller has an individual SD card), the file placement for each controller SD card would be like this: the first two digits stand for the program number (00 to 16). Since we use a single SD card for each controller, the last digit is always “1“.

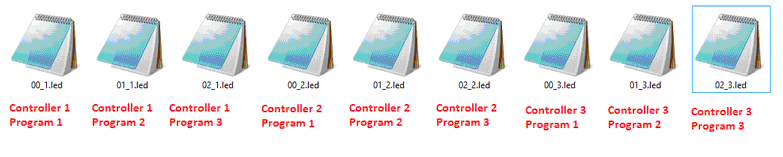

If you are using multiple controllers networked together, you only need a single SD card inserted into the first controller in the network. You can place each controller's program on that SD card.

The above picture shows how to place those program files. The first two digits stand for program number (00 to 16). The digits after the “_” character are the controller number, starting from “1“.

Eg:

This may be due to a few reasons:

The controller cannot detect a damaged SD card, an unsupported SD card, or an unsupported file format.

Fix:

This is due to a physical error: damaged wires in the LED string, damaged or oxidized ports or connectors, or selecting the wrong drive chip type in the new project window. If the ports are damaged, you have to re-solder them. If connectors are oxidized, you have to use NC-Tinner to clean them. You can use a used toothbrush and dip it in NC-Tinner and brush the oxidized parts of the controller and the LED string, or use contact cleaner spray.

Hot Swapping: Never pull out or remove the SD card from the controller while the power is on (this will damage your SD card permanently, or if you are lucky, you can get away with only the file lost or damaged). Always power off the controller, wait for a few seconds, and remove the card.

Never reverse the polarity: Reverse polarity protection may or may not be in your controller or LED string. If there is no protection, it will damage the controller and Pixel LED Driver I.C. Use a multimeter to check the polarity of the power supply output before wiring.

Since there are thousands of different manufacturers, wire colors may change with the manufacturer. Please contact the seller or the manufacturer before wiring. If not, it may cause damage to the driver's chip.

Check the feedback of the sellers before buying online. There are many fake or damaged controllers. Pixel LED strings are available on the internet. (Be aware of scammers.)

Limit the amount of time you spend inserting and removing the SD card from the controller, because every time you do this, it will cause the gold-plated pins to scratch, which will lead to the oxidizing of the pins.

Environmental conditions may cause damage to your LED string and the LED controller. The controllers are not designed for outdoor use; they're for indoor use only. If you are putting the LED string outside, please make sure to use the water-sealed LED strings. However, even the water-sealed LED strings may be damaged due to harsh environmental conditions.

Out A to input A out B to input B one controller to another controller wire distance and wire gauge